The quality of the bolts and nuts used in assembly has an enormous effect on the quality of screwed joints.

Performance tests are the most important type of analysis for use in assembly processes. They determine the mechanical properties and tolerances of the fastener components, in order to ensure that they fulfill their performance requirements.

SCHATZ®-ANALYSE enables you to make tests in accordance with international standards or under realistic conditions corresponding to actual assembly processes.

We got the first 2000Nm double head analyze system in Taiwan, which meet VDA23-203, ISO16047 and ISO2320 with test range from M4~M24 and 2000Nm side is 75rpm, 500Nm side is 330rpm.

The salt spray test is a standardized and popular corrosion test method, used to check corrosion resistance of materials and surface coatings. Usually, the materials to be tested are metallic and finished with a surface coating which is intended to provide a degree of corrosion protection to the underlying metal. Salt spray testing is an accelerated corrosion test that produces a corrosive attack to coated samples in order to evaluate (mostly comparatively) the suitability of the coating for use as a protective finish. The appearance of corrosion products (rust) is evaluated after a pre-determined period of time. Test duration depends on the corrosion resistance of the coating; generally, the more corrosion resistant the coating is, the longer the period of testing before the appearance of corrosion/ rust. The salt spray test is one of the most widespread and long established corrosion tests. ASTM B117 was the first internationally recognized salt spray standard, originally published in 1939. Other important relevant standards are ISO9227, JIS Z 2371 and ASTM G85.

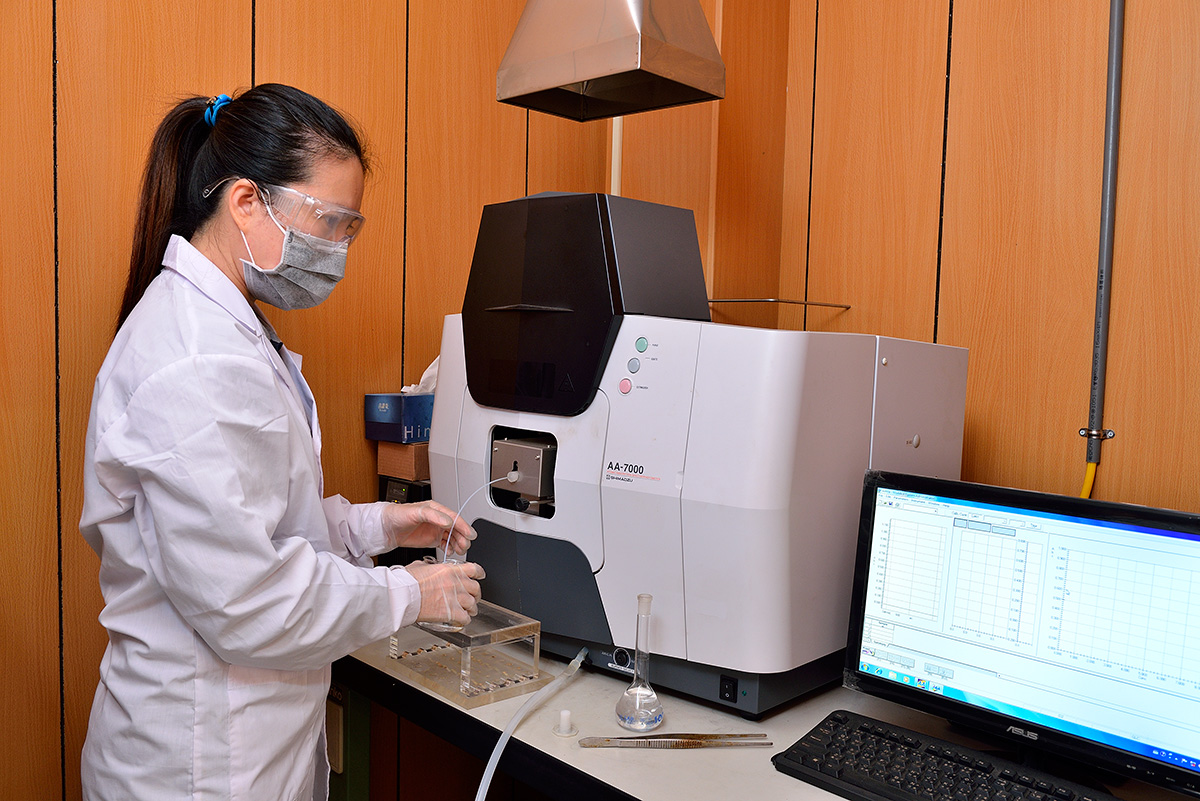

Atomic absorption spectroscopy (AAS) is a spectroanalytical procedure for the quantitative determination of chemical elements using the absorption of optical radiation (light) by free atoms in the gaseous state.

In analytical chemistry the technique is used for determining the concentration of a particular element (the analyte) in a sample to be analyzed.

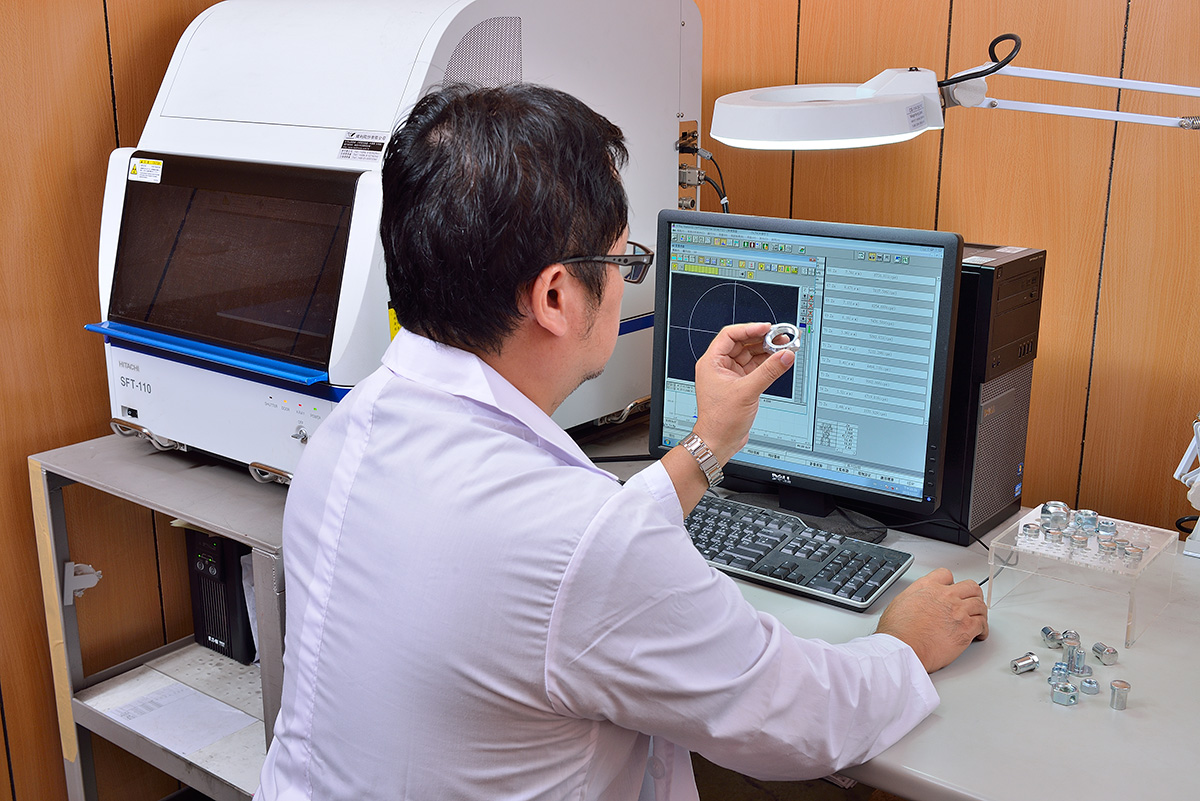

Determine the coating thickness by X-ray without contact and damage samples. Widely used in quality management and defected product analyze.

Ultraviolet–visible spectroscopy or ultraviolet-visible spectrophotometer (UV-Vis or UV/Vis) refers to absorption or reflectance spectroscopy in the ultraviolet-visible spectral region. This means it uses light in the visible and adjacent (near-UV and near-infrared [NIR]) ranges. The absorption or reflectance in the visible range directly affects the perceived color of the chemicals involved. In this region of the electromagnetic spectrum, moleculesundergo electronic transitions. This technique is complementary to fluorescence spectroscopy, in that fluorescencedeals with transitions from the excited state to the ground state, while absorption measures transitions from the ground state to the excited state.

UV/Vis spectroscopy is routinely used in analytical chemistry for the quantitative determination of different analytes, such as transition metal ions, highly conjugated organic compounds, and biological macromolecules.

Hull cell analysis of a plating bath electrolyte is more of an art than a science. While some guidelines do exist, only time and experience (and VERY GOOD record keeping) will provide the tools you need to quickly, and accurately determine the state of your bath.