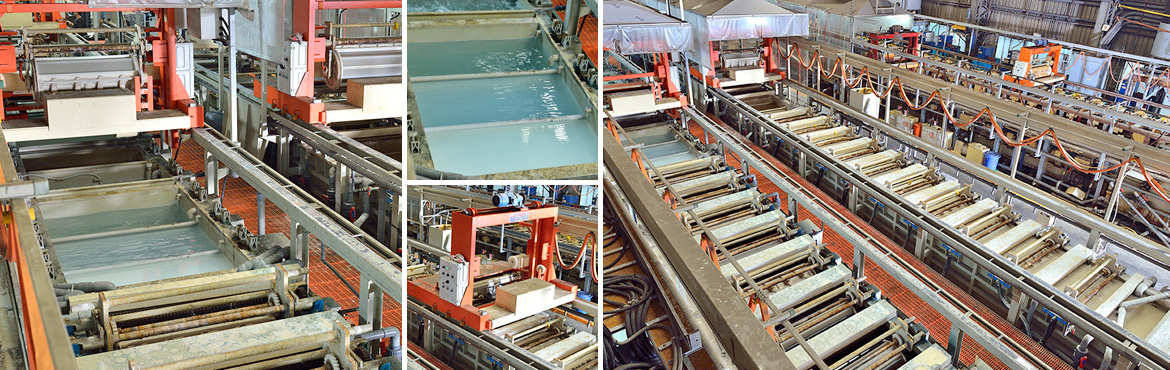

Production Equipment

Zinc Plating & Passivation

- Provide corrosion protection

- Often used for part identification – can be used with a variety of topcoats to provide various appearances

- Cost-Effective Coating

- Non-Toxicity

- Electrical insulation. Conductivity

- Many Automotive Uses

- Corrosion resistance ability(with sealer):240 hours no white rust and 1000 hours no red rust

- Zinklad Approved

Passivation

The development of Trivalent Cr(III) for use in Passivates has become necessary in recent years as a result of the ELV, RoHS, Reach and WEEE.

The elimination of hazardous substances from coatings has resulted in the ban of Cr(VI) from corrosion protection layers and forced the industry to convert to Cr(III) based post treatments.

Our trivalents meet the requirements of the new RHOS, ELV, WEEE and Reach regulations. In addition to clear trivalents, we offer iridescent and yellow trivalents.

Mainly use Dipsol ZT-444 which has iridescent color. In addition, MacDermid and Columbia also can be choosen.

Chemical Supplier